The factory of tomorrow is being built in Saint-Imier

Join the MicroLean Lab to put Industry 4.0 to work for you

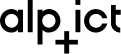

The Haute Ecole Arc Ingénierie presents the MicroLean Lab to industrialists during the first three weeks of November. Its aim is to experiment with the concepts of industrial digitalization through the vision of a connected, autonomous and reconfigurable microfactory destined to revolutionize the microtechnology industry. This is the first time this demonstrator has been unveiled publicly.

The MicroLean Lab will be on show from November 3 to 19 in its new setting at the Saint-Imier Technology Park. Around a hundred industrialists have already signed up for the "micro-visits" offered on Tuesday, Wednesday and Thursday afternoons during this period. Visits are limited to ten people per hour. To register for a visit, please go to this page.

A connected, autonomous, reconfigurable microfactory set to revolutionize the microtechnology industry

The team will be delighted to show you its prototype microfactory and tell you how you can work with the MicroLean Lab.

This demonstrator comprises a series of technological blocks required for the manufacture of high value-added microtechnology products. From the stock of raw materials to the finished product, parts and tools move from one block to the next in an agile and autonomous manner. By exploiting the data collected and analyzed during the manufacturing process, the microfactory's artificial intelligence enables production parameters to be adapted in real time, guaranteeing parts right the first time.

Experimenting with digitalization while meeting socio-economic and environmental challenges

"Our aim is to offer the Swiss microtechnology industry the opportunity to experiment with the potential of digitalization," explains Florian Serex, head of partnerships and development at MicroLean Lab. For the time being, this experimentation center has been set up as a community of interest, bringing together four major watchmaking groups and a dozen small and medium-sized enterprises (SMEs).

The MicroLean Lab is not just a response to digitalization, but also to today's socio-economic-environmental challenges. Microfactories will enable us to manufacture and consume products in a much more sustainable and responsible way.

Given the reduced size of the technology blocks, they will consume much less energy and floor space than current factories. If we take as a reference the micro, a 5-axis milling machine developed in 2016 by HE-Arc Ingénierie and now integrated into a block of the micro factory, it occupies five times less floor space and consumes ten times less energy than traditional machines.

A renovated, forward-looking showcase in the Jura Arc region

This November's "micro-visits" will also enable industrialists to discover the renovated MicroLean Lab. Following an initial extension to the building in 2012, HE-Arc and the town of Saint-Imier, through the company Parc technologique de Saint-Imier SA, have invested 1.5 million francs in the renovation and transformation of the southern part of the building, which corresponds to a former Straumann factory dating from the 1960s.

The renovation of this protected building blends modernity and industrial history, reflecting a forward-looking engineering school and industrial fabric with deep roots in the Jura Arc. This breeding ground is home to know-how that is unique in the world, and is preparing the next generation of engineers to perpetuate the region's highly industrial heritage.